Concept

What is a Meta Printer?

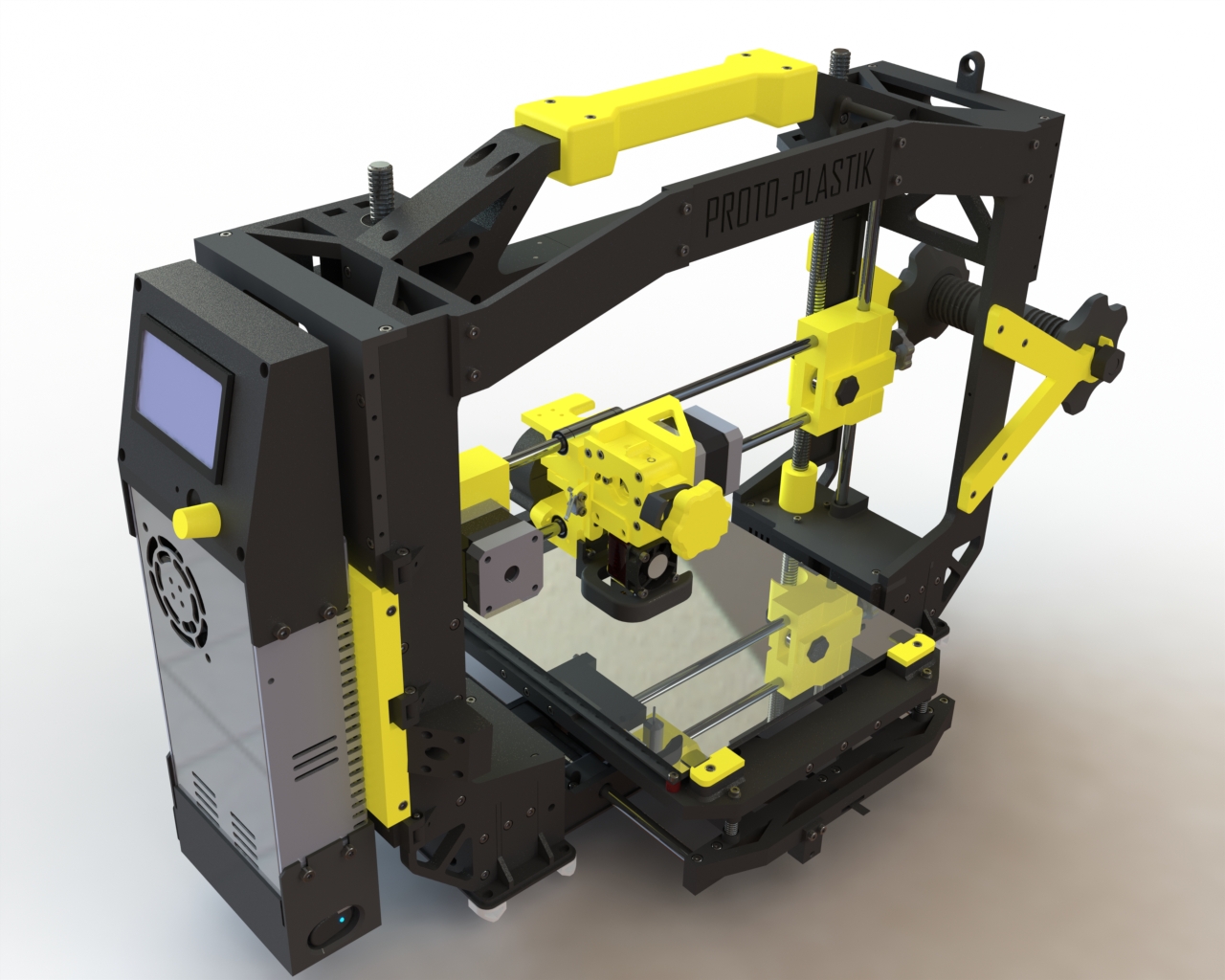

In support of develping the concept of Micromanufacturing, we have designed the A5 line of printers. By creating printers that print other printers, we have the ability to scale up our production capabilities to match growth in our business. With over 80% of the components on the printer being themselves printed, there are a number of advantages.

-

Open Source

TRUE open source architecture. With each printer purchased, you will have access to all, fully editable digital files for modding, upgrading, or completely changing the design. Files will be available via GitHub for source and version control. Development of these printers will be ongoing allowing you to upgrade your printer as new development takes place.

All source files are available at our Github Site.

-

Scaleability

Use a single printer to spawn an entire manufacturing workflow. Scale your production as your needs grow. Build mission-specific printers for use of specialized filament.

-

Flexibility

Flexibility to utilize any of your favorite components. Want to upgrade from the RAMPS board? No problem! Always wondered what it would be like to use anti-backlash components? The drivetrain is easily accessible for mods. This printer was designed by 3D Printing Enthusiasts FOR 3D Printing Enthusiasts.

Design

The designation 'A5' refers to the X-Y dimensions being roughly the same as an A5 sheet of paper.

Our printers use the same component footprint as the popular QUBD TwoUp printer with improved engineering to provide a 40% increase in volume. As a result, owners of the QUBD TwoUp can purchase an A5 kit that contains all the printed parts needed to build a Proto-Plastik Meta Printer. You'll get the added advantage of an increase of 40% build volume!

While there are many printers out there with dual z-axis supports. We have found with the right amount of ingenuity, the same quality and consistency can be obtained with a single z-axis. This makes things like wiring up the controller board and bed tramming (leveling) a snap. The anti-sag belt, inspired by several others who were searching for ways to eliminate sag on the QUBD printers, ensures that the x-axis maintains orientation throughout the entire print run.

All Proto-Plastik A5 Meta Printers include:

- 180mm x 195mm x 160mm Build Area

- Screw-togther construction utilizing readily available M3 screws (we'll even throw in the best 2.5mm screwdriver on the planet from Bondhus)

- Built from durable and environmentally friendly PLA material

- Positive belt tightening on the X and Y axes that ensures dimensional consistency

- 8 'hard points' for mounting the printer to a rigid surface. This improves print quality on all printers, including the Club

- Exclusive Proto-Plastik Direct Drive extruder that does not need springs.

- Unique 'CenterDrive' drive system for the bed

- Industry standard hardware including:

- LM8 bearings

- 8mm rods

- GT2 20T drivetrain

- MK8 filament gear

- All Metal E3D Hotends (V6, Lite6, etc)

- 3/8" ACME Threaded Z-Axis rod

- The venerable RAMPS 1.4 Arduino-based controller board

Value

Designing the printers to be manufactured from printed parts isn't just a novelty. 99% of the printers on the market today require large-volume manufacturing including injection molded parts, aluminum machined parts, routed or laser cut parts, or stamped metal parts. Many of those companies claim that their printers are 'open source'. They provide digital files of all the parts, but unless you have a fully stocked machine shop, it's unlikely you'll be able to actually make any of those parts.

From the time you get your first printer built, you will be able to start right away with building another printer. It takes about 4 days to print out all the parts for a second Club model printer. Or you can begin right away at printing the parts needed to upgrade to the Maker or Professional. We can also provide all the hardware needed to build your second printer.

Please Contact Us

If you are interested in purchasing a kit or complete printer, we have many options available and our price list is coming soon. In the meantime, please contact us at: rick@proto-plastik.com